Industries

Clemex serves many Fortune 500 companies in various manufacturing industries, with a particular focus on the automotive, aerospace, and metal processing sectors. Our fully automated image analysis solutions aim at assisting technicians, engineers and researchers around the globe in streamlining their testing.

METALS

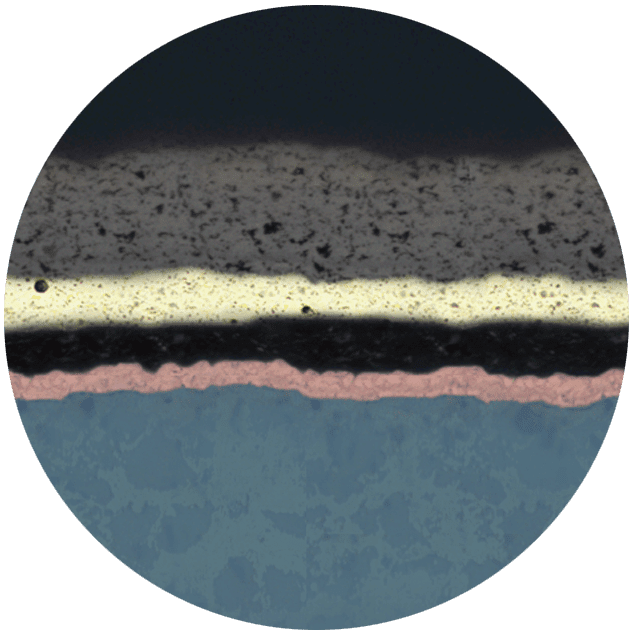

Clemex provides accurate automated image analysis for the metal industry, and more specifically for laboratories of steel, aluminum, cast iron, copper and powdered metal product manufacturers, including those specialized in 3D printing.

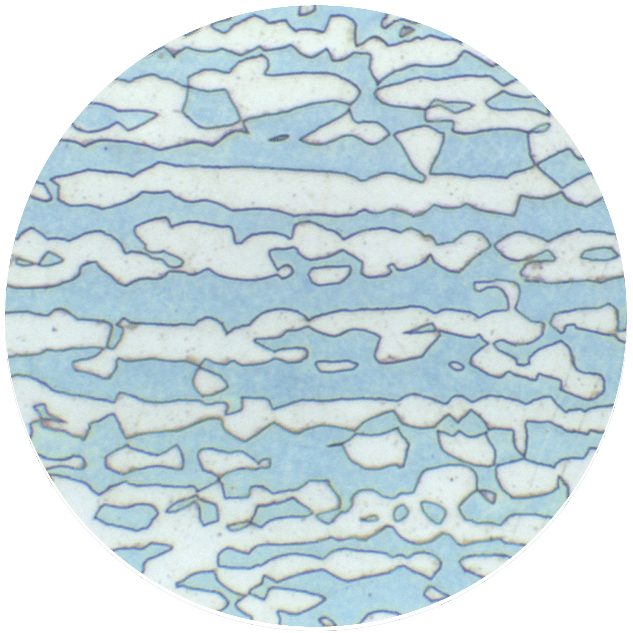

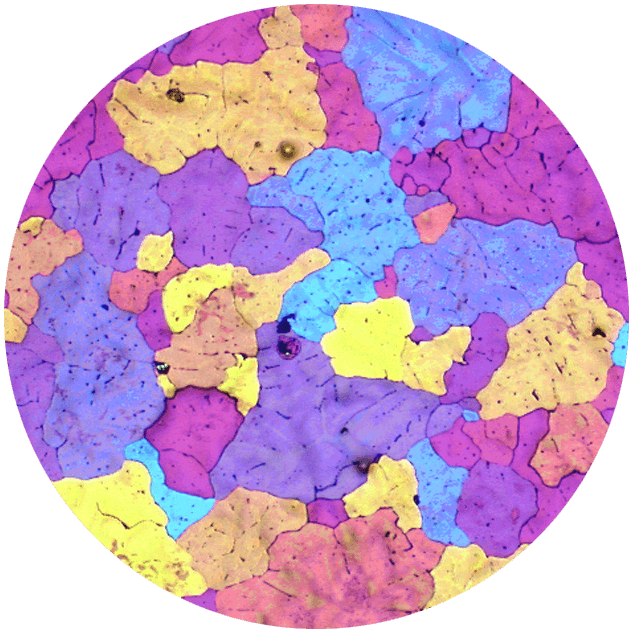

Customer material testing facilities equipped with our systems are able to adapt any industry standard to their testing procedure. Common tests on incoming and outgoing materials rely on efficient microstructure analysis, such as nodularity, porosity, inclusions, grain size, inverse segregation, phase area and DAS. Clemex systems perform these measurements day in day out with minimum user input and with unsurpassed reliability.

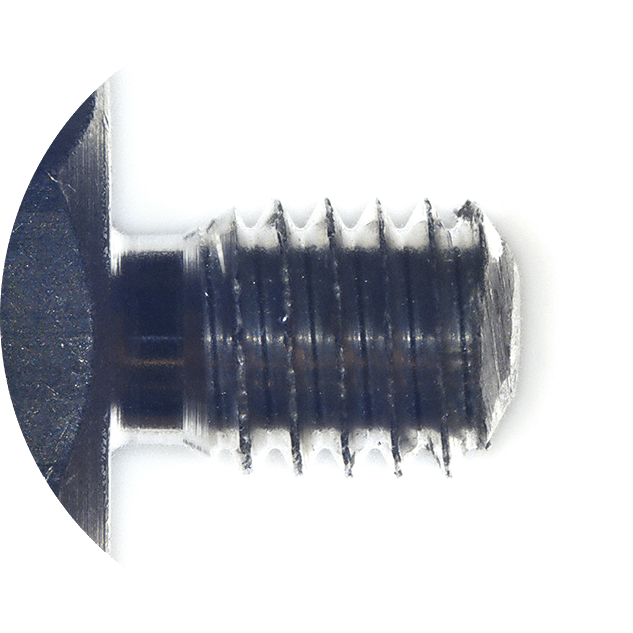

AUTOMOTIVE

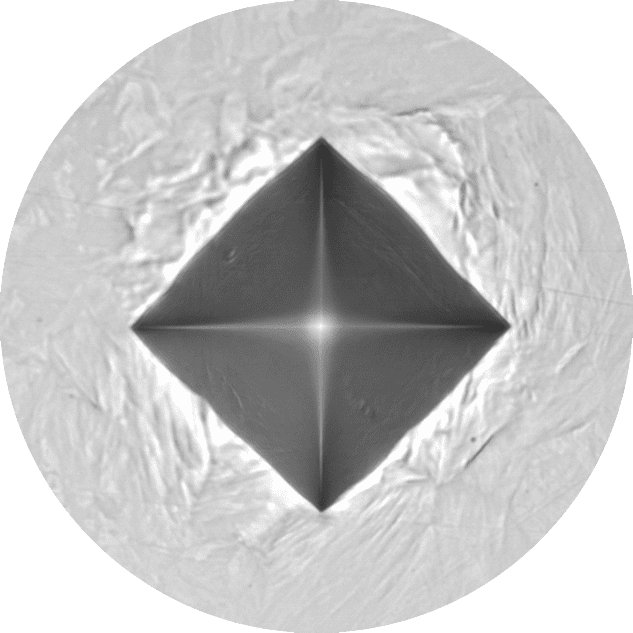

We provide automotive companies with testing solutions for hardness testing, contaminant analysis, and quantitative metallography for a vast array of vehicle parts. We automate microstructure analysis of incoming and outgoing materials to ensure critical components have the required physical properties for use in end products.

AEROSPACE

Our superior imaging systems can conduct these essential analyses for satellite parts, helicopter components, jet engines, and more so you can bring your products to market with total confidence. We also help aerospace companies evaluate contaminant levels in cleanrooms.

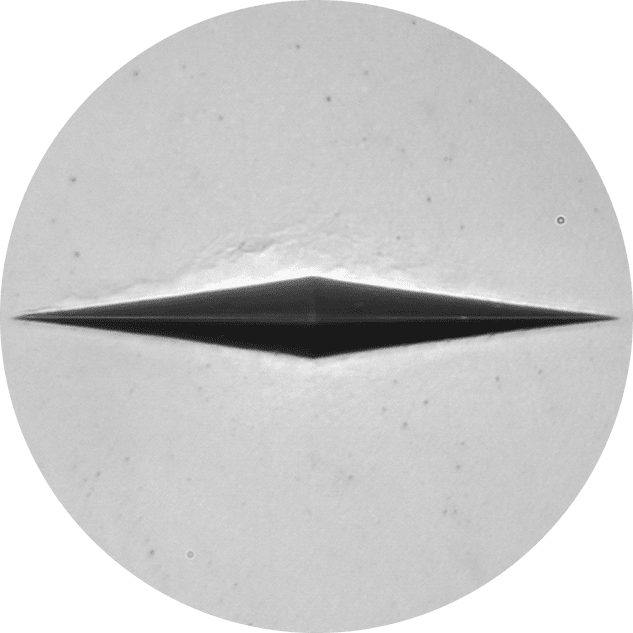

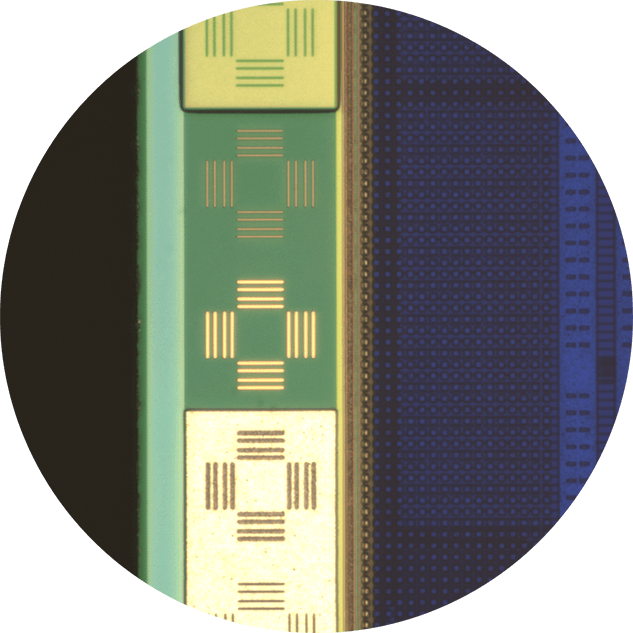

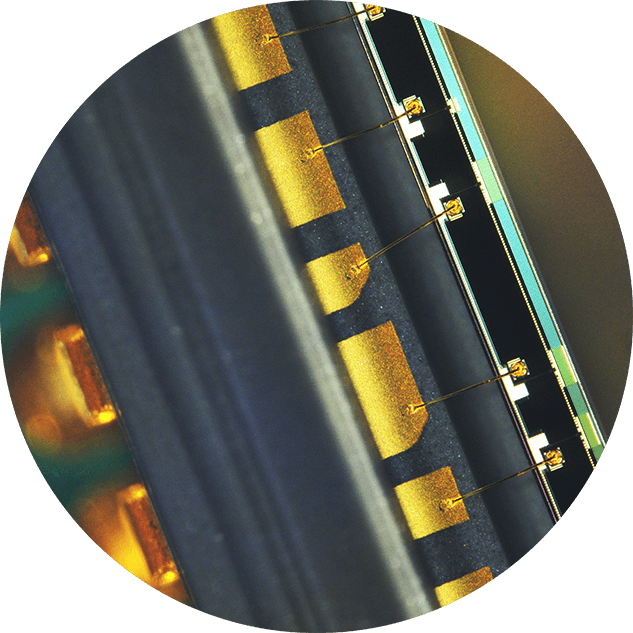

MICROELECTRONICS

With our cutting-edge technology and expertise, we can solve the industry’s most challenging problems such as defect detection in semiconductor wafer inspection. We can inspect many types of surfaces and validate their integrity using the power of image analysis vision technologies and auto-stage controls.

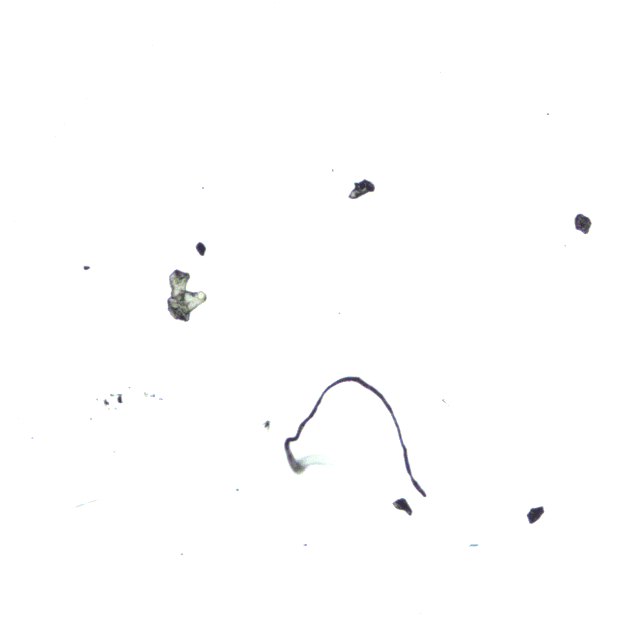

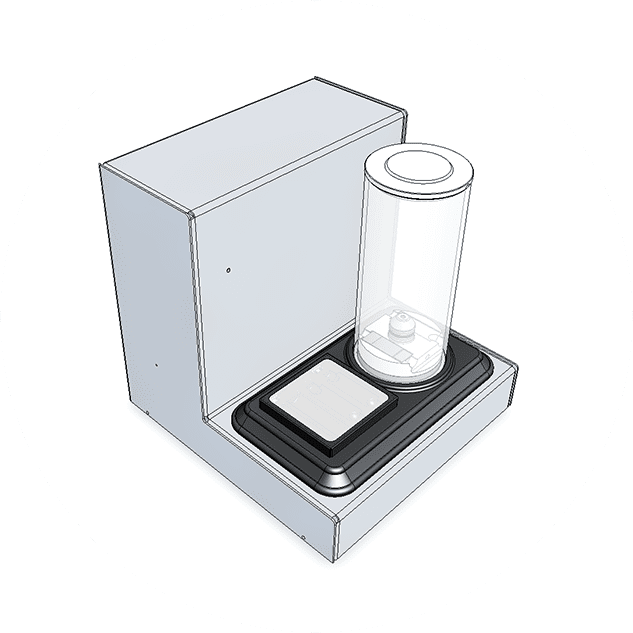

PHARMACEUTICALS

For pharmaceutical laboratories, accuracy of particle measurement is of critical importance when assessing active ingredients in dry powder medication. Drug concentration, dissolution and release rate are affected not only by particle size but also shape.

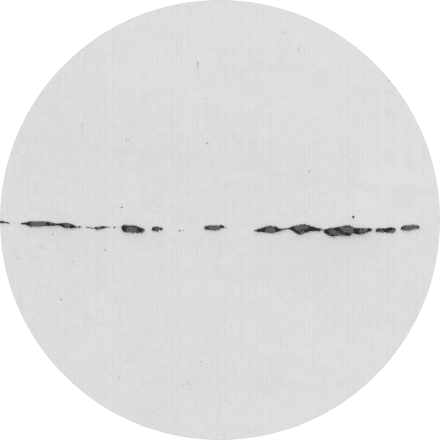

Automated image analysis allows research and quality control scientists to process an unlimited number of particles, giving real-time access to statistically significant results for each category of particle, whether circular, flake- or needle-like (acicular), ranging from 0.5 to 1000 microns. User Management module is included with our software to conform with CFR 21 Part 11 requirements.

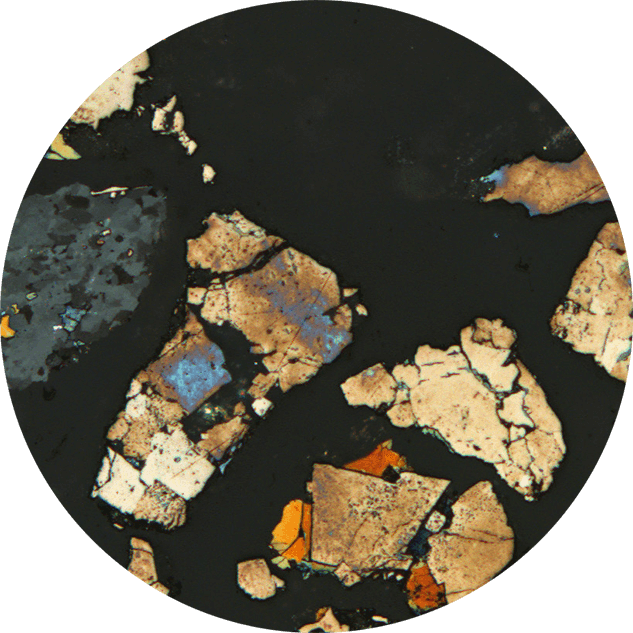

MINING

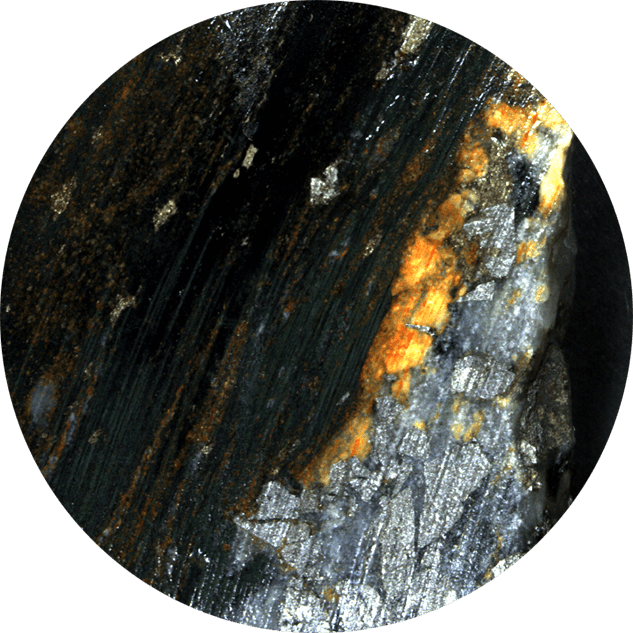

The mining industry needs more effective and efficient techniques to meet the future challenges of environmentally sound mining methods. Mineralogical data is an essential contribution in improving the knowledge on ore and wastes, and could bring major advances in mineral processing, and integrated waste management.

Optical microscopy is used identify and quantify common sulfides: arsenopyrite, chalcopyrite, galena, pyrite, pyrrhotite, and sphalerite. Clemex software has potential for deeper mineralogical analysis, such as mineral liberation, mineral associations, texture identification and quantification, and particle size distribution.