THE MOST ADVANCED

IMAGE ANALYSIS SOLUTION

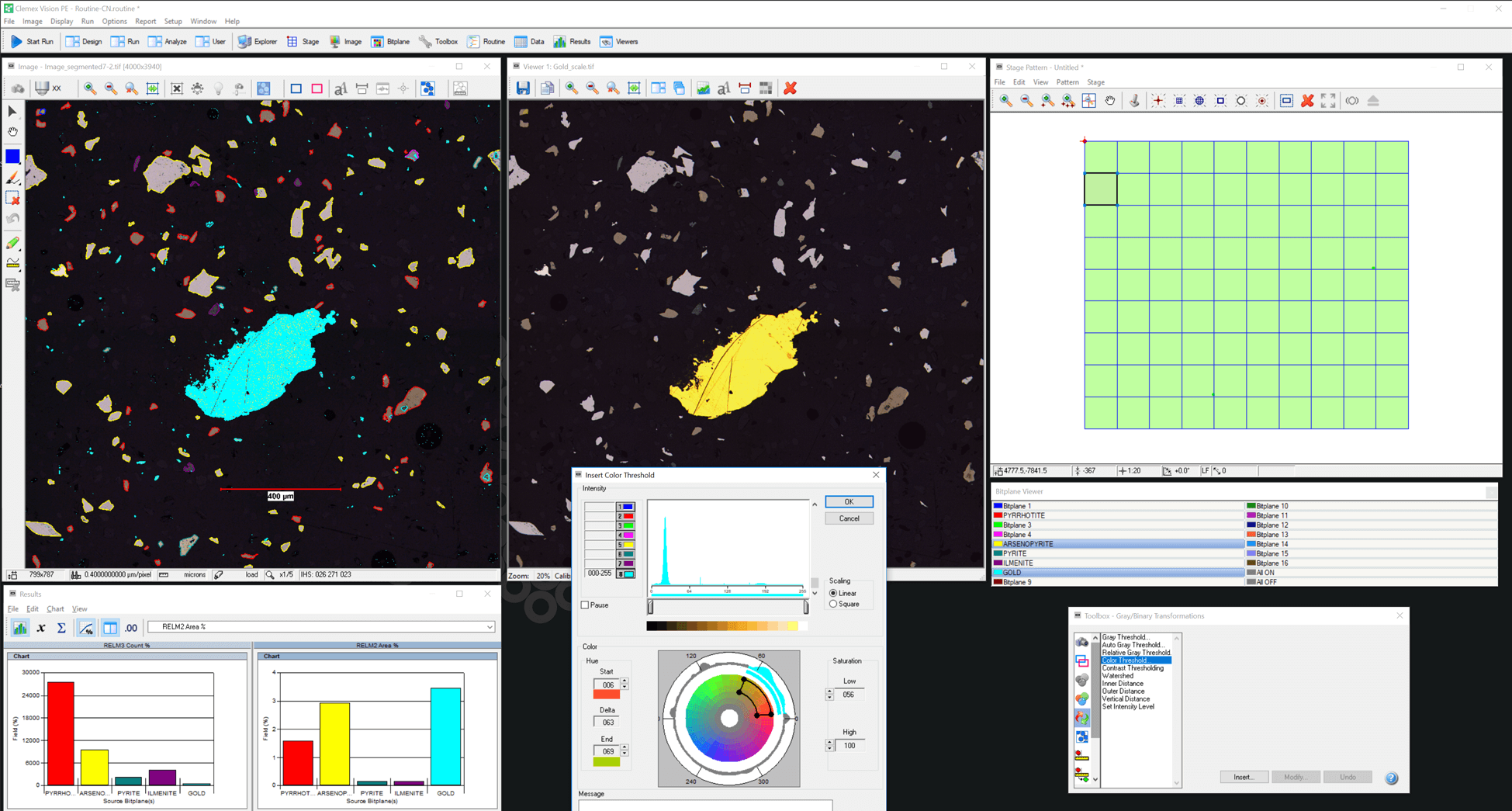

Clemex Vision is a fully integrated system for labs seeking traceable, repeatable, and accurate results. This is our most powerful automated image analysis system. It includes a great range of computer vision functions, catering for various applications in industry and research. Our image analysis software is exceptionally flexible, allowing for any number of distinct routines to be run on the same system. These routines come packaged as a library of existing applications or can be developed by our application specialists.

APPLICATION PACKAGES

ANALYSIS TYPES

STANDARDS

- ASME B46.1

Surface Texture (Surface Roughness, Waviness, and Lay) - ASTM A247

Microstructure of Graphite in Iron Castings - ASTM B487

Measurement of Metal and Oxide Coating Thickness - ASTM E1077

Depth of Decarburization of Steel Specimens - ASTM E112

Average Grain Size

- ASTM E1245

Inclusion or Second-Phase Constituent Content of Metals - ASTM E1268

Degree of Banding or Orientation of Microstructures - ASTM E562

Volume Fraction by Systematic Manual Point Count - DIN 17230

Ball and Roller Bearing Steels - ISO 945

Microstructure of Cast Irons

KEY FEATURES OF CLEMEX VISION ANALYSIS SOFTWARE

Universal Grain size analysis

With the AI Plugin “GrainSeg”, segmenting even the most difficult images is fast and reliable. You can analyze copper alloys, austenitic steels or titanium alloys containing twins and it supports all methods of the ASTM-E112 standard.

CUSTOMIZE YOUR ANALYSIS

Detect, characterize and measure phases or objects of interest using our extensive instruction library. You can easily combine any set of instructions and create your own routine.

MARTENSITIC GRAIN SIZE INSTRUCTION

The powerful Martensitic functionality is inserted at the beginning of an automated image analysis routine to detect the boundaries of grains. Several parameters allow the user to fine-tune detection.

POWERFUL PROCESS AUTOMATION

Quicker analysis time is made possible with this robust software capable of processing thousands of images and generating data all day long without human intervention.

TRACEABLE DATA

Validate detected features and delete artifacts across multiple fields using the Map and Go function. Object data in the built-in spreadsheet are dynamically linked to the actual position of the objects on the sample.

ANALYSIS PROPERTIES

Information from property fields can be automatically inserted into reports, file names or folder names. Use standard properties such as Magnification, Date or Sample Name or create custom fields.

AUTOMATED REPORTING

Reports are generated automatically after each analysis and can be adapted to suit your needs. Add a company logo, images captured during analysis, graphs and statistics, and save your results as a csv, xlsx or pdf file.

MOSAIC IMAGE STITCHING

CFR 21 PART 11 COMPLIANCE

With the User Management module, administrators can add users, create user groups, and trace events in the audit trail. This optional module allows electronic signature embedding and is secure and reliable.

MORE FEATURES

- ACCURATE DETECTION

Detect objects that are difficult to distinguish because of their their transparency, low contrast or faint outlines. - CLASSIFY OBJECTS

Isolate objects using any measurement type (length, width, aspect ratio, roughness, etc.). - CONDITIONAL INSTRUCTIONS

Analyze objects that meet certain criteria, such as size, shape or orientation.

- DIRECT MEASURES & ANNOTATIONS

Annotate your images on-the-fly during your analysis; include results and visuals in reports. - EXTENDED DEPTH OF FIELD

Obtain a sharp composite image made up of several image slices, perfect for uneven surfaces. - EXTERNAL DEVICE CONTROL

Activate external devices such as valves, locking devices, alarms, lights. - IMAGE OPTIMIZATION

Shading correction, auto-exposure, white balance, auto-focus, parfocality and paraxiality for each magnification. - MOTORIZED STAGE CONTROL

Controlled through the software, scanning regions can be defined using pre-built templates.

- NIST-TRACEABLE CALIBRATION

Eliminate operator subjectivity by automatically calibrating each lens using a NIST-traceable micrometer. - SEPARATE OBJECTS

Separate adjacent objects automatically prior to performing measurements. - SCAN REGION AUTOMATION

Automated stage pattern creation based on detected objects or sample reference points. - THIRD PARTY IMAGES

Import images from various sources, such as SEMs or scanners.

VISION CORE

VISION LITE

CAPTIVA

Virtual Joystick for motorized stage + autofocus

✓

✓

✓

Save & Export Measurements

autom.

autom.

man.

Save & Export Images

✓

✓

✓

Manual Measurements & annotations

✓

✓

✓

Report Generator

optional

optional

n/a

Unlimited Routines

✓

limited tools

n/a

Automatic Measurements (field/ objects)

✓

✓

n/a

Custom Measurements (field/ objects)

✓

✓

n/a

Thresholding

+ processing

✓

✓

✓

n/a

n/a

n/a

Advanced Operations

✓

optional *

n/a

Automatic Transfer

✓

optional *

n/a

* available together with one or more application modules

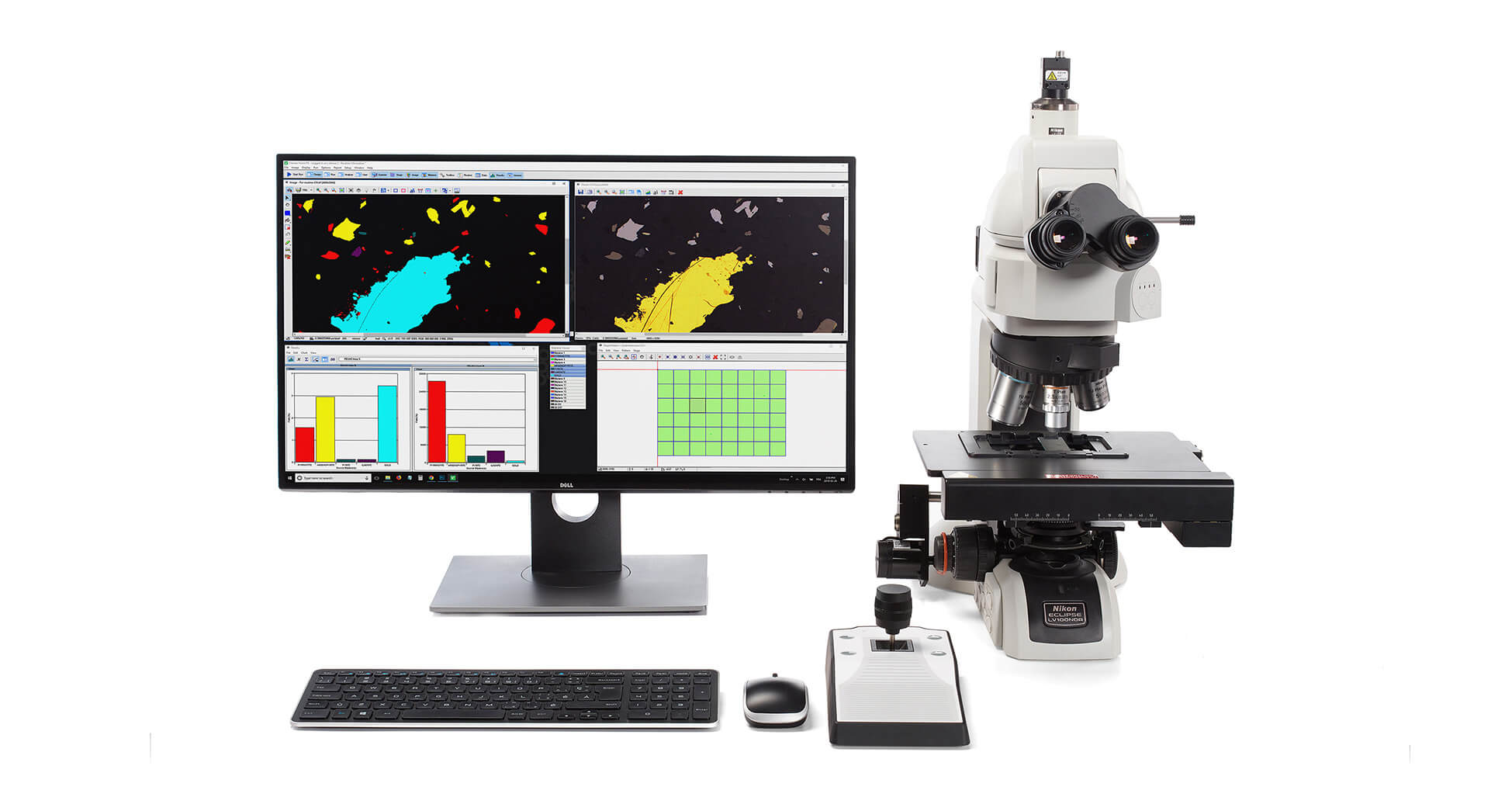

BUILD YOUR COMPLETE IMAGE ANALYSIS SOLUTION

Typically an upright microscope, a motorized stage, and a high-resolution camera are selected to fit your specific image analysis needs. We ensure a seamless integration of all components.

- Analysis of your needs by a technical representative

- Configuration, fine-tuning, and calibration

- On-site installation and training of your team

CAMERAS

High resolution cameras to fit demanding optical imaging applications.

NIKON MICROSCOPES

We integrate quality stereo, upright, and inverted Nikon microscopes.

LEICA MICROSCOPES

We integrate quality stereo, upright, and inverted Leica microscopes.

MICROSCOPE STAGES

Märzhäuser-Wetzlar stages, controllers and joysticks work with many different brands of microscopes.

CUSTOM STAGE ACCESSORIES

We design and manufacture a wide range of sample holders and stage adapters, produced to meet any customer specifications.

STAGE MICROMETER

The Clemex stage micrometer for automatic calibration and shading correction; comes with a NIST traceable certificate.