PROGICIELS D’APPLICATIONS

D’ANALYSE D’IMAGES

Ces routines prédéfinies et ajustables sont offertes avec Vision Unlimited et sont en option avec Vision Lite. Un progiciel contient plusieurs exemples de routines pour présenter différentes images d’un même type d’application. Chaque progiciel d’applications contient également un tutoriel de routine avec des étapes clairement définies pour montrer comment ajuster les paramètres.

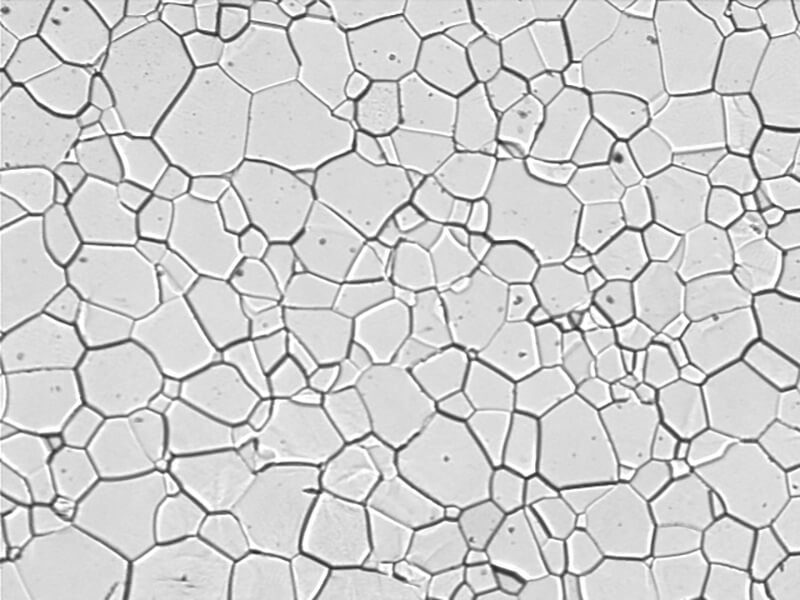

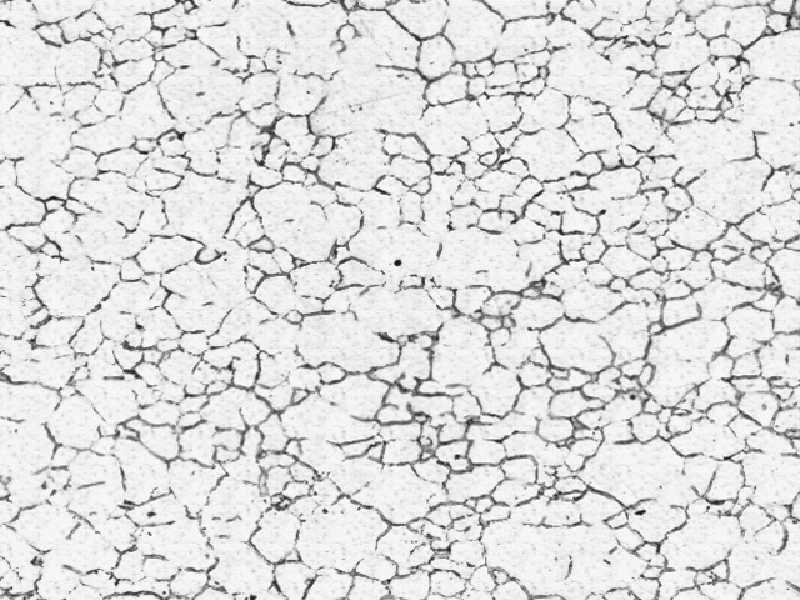

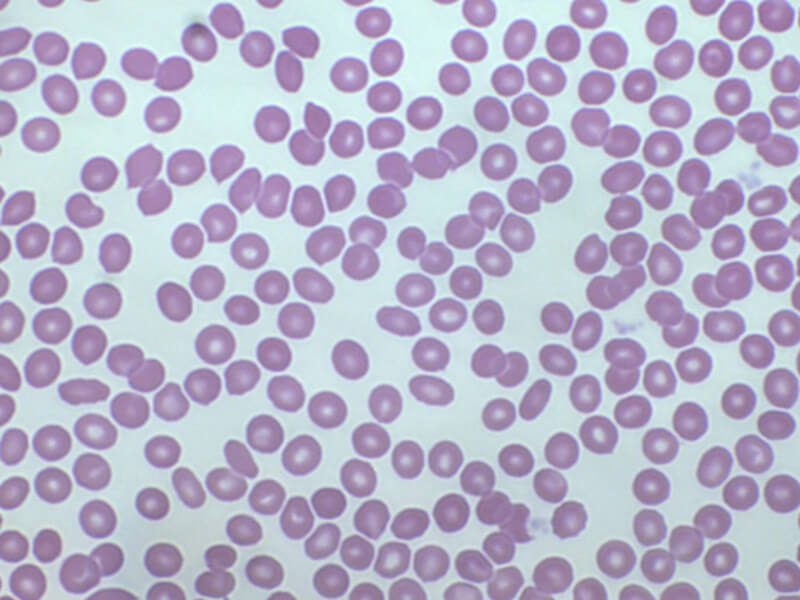

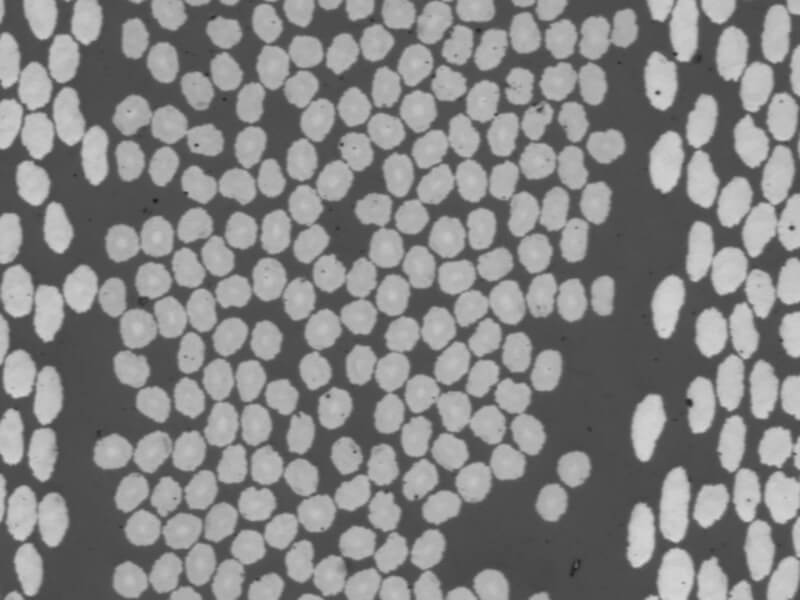

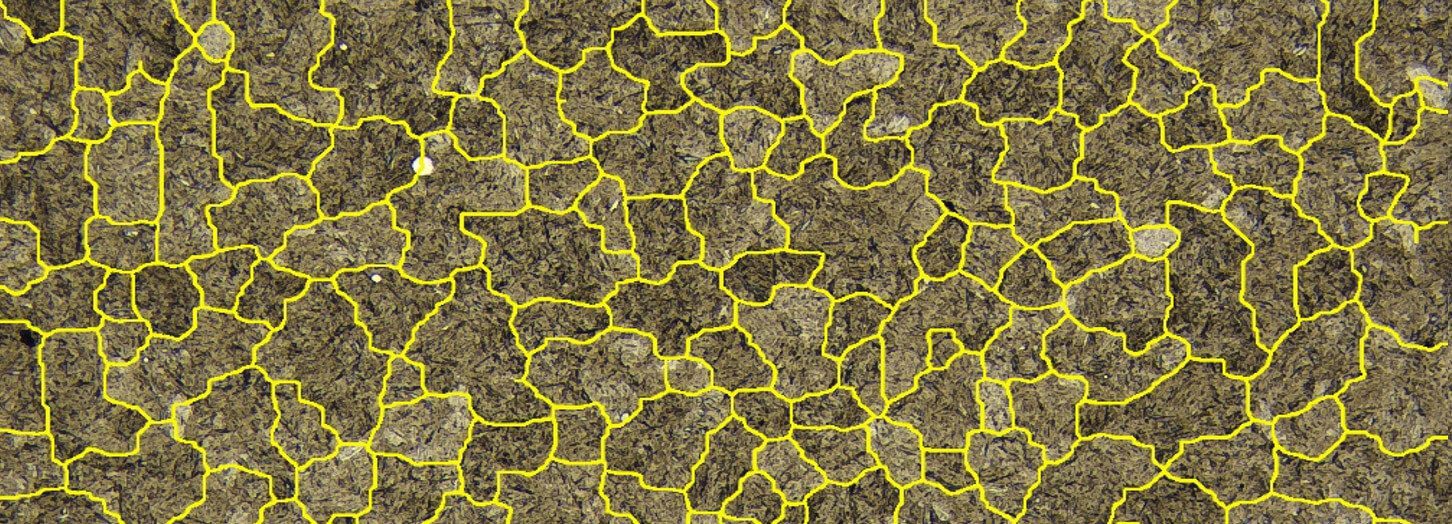

TAILLES DE GRAINS ET DE CELLULES

Permet aux utilisateurs de mesurer les points d’intersection des grains, le nombre de points d’intersection, le nombre d’intersections,

la longueur des joints de grains et les zones de grains conformément aux normes ASTM E112, ASTM E930

et ASTM E1382, avec vérification à l’aide de la méthode Heyn.

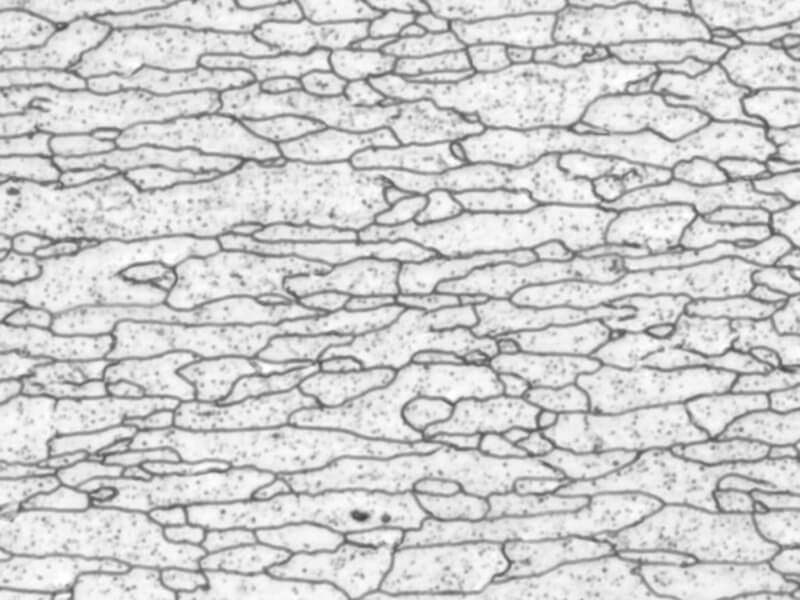

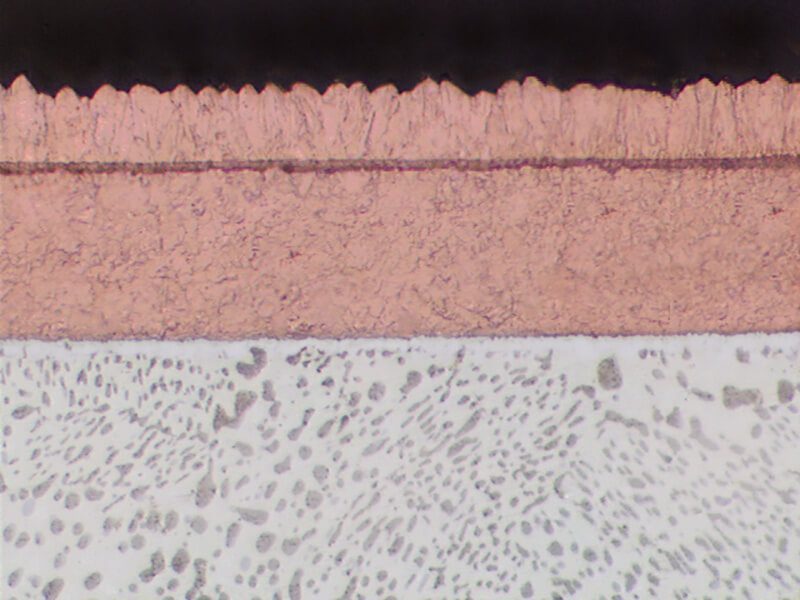

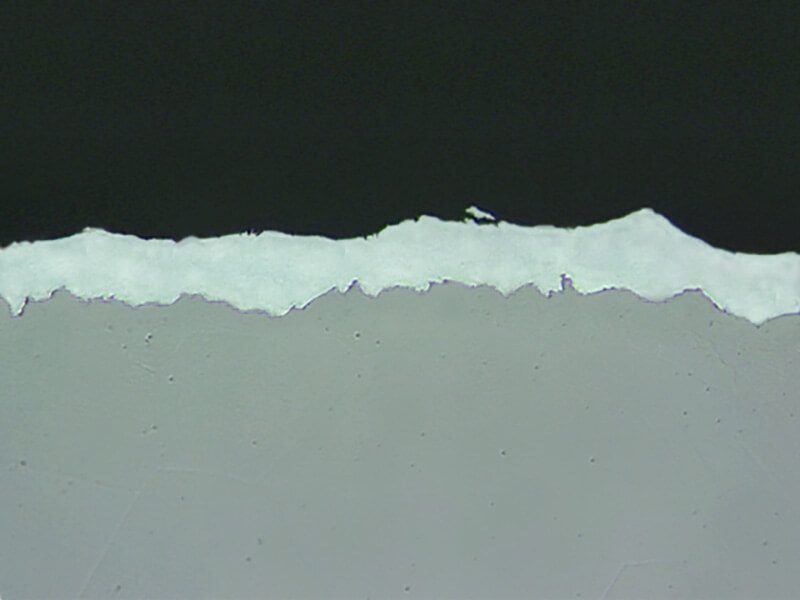

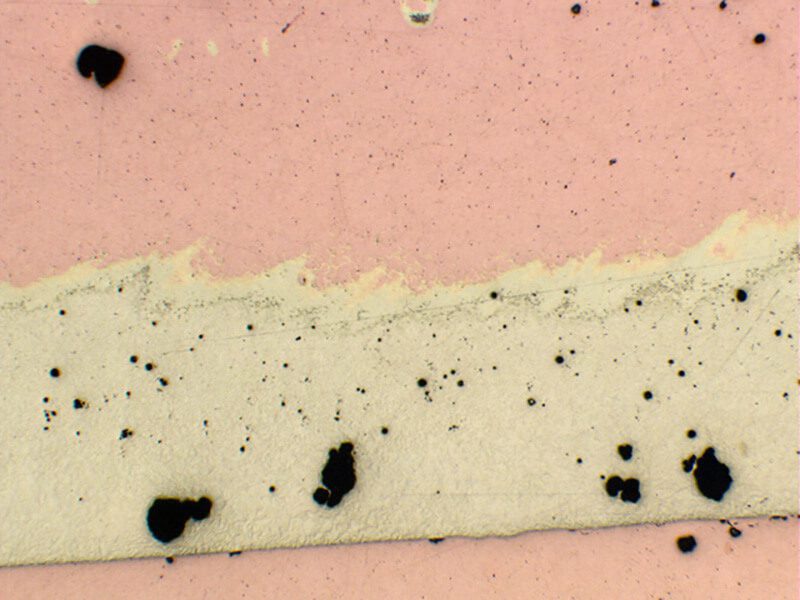

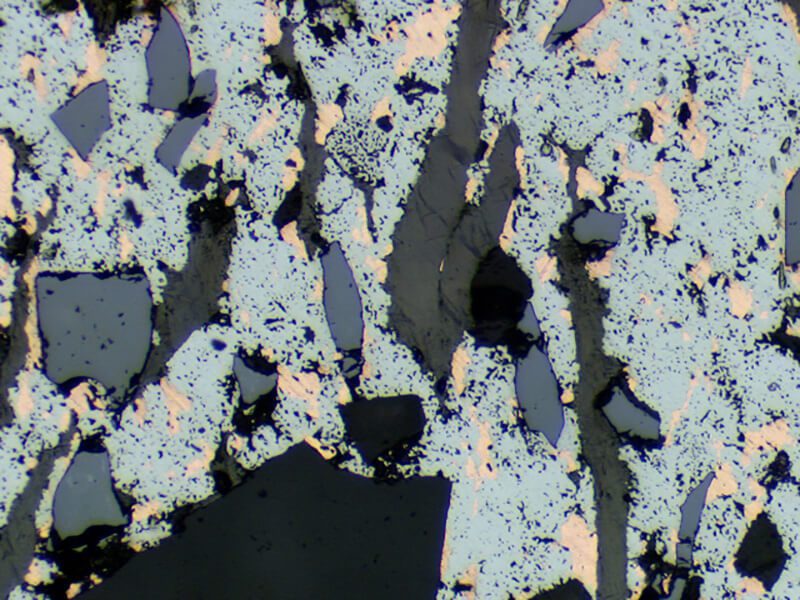

ÉPAISSEUR DE COUCHE

Permet aux utilisateurs de mesurer l’épaisseur des couches de surface minces sur les métaux,

les alliages, les carbures et les oxydes (ASTM B487). Il existe une variété de routines,

allant d’une couche de revêtement poreux à plusieurs couches de différents types de revêtement.

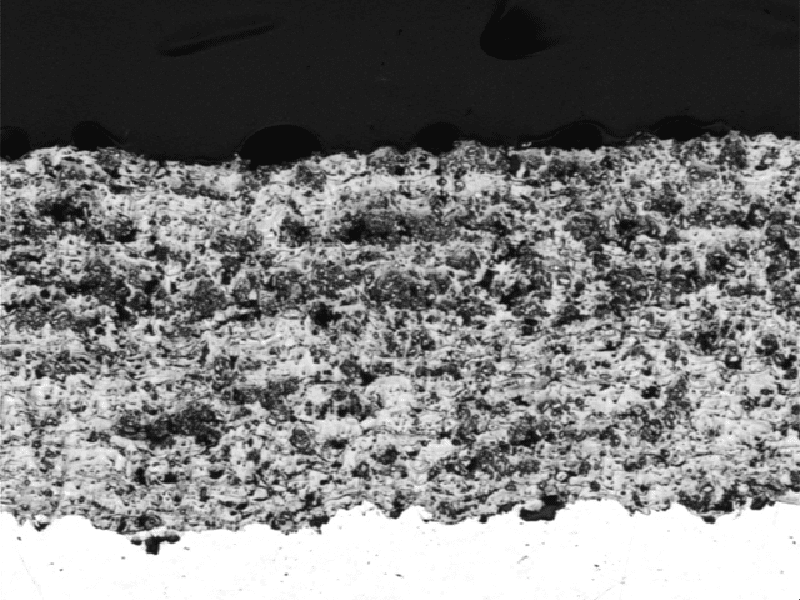

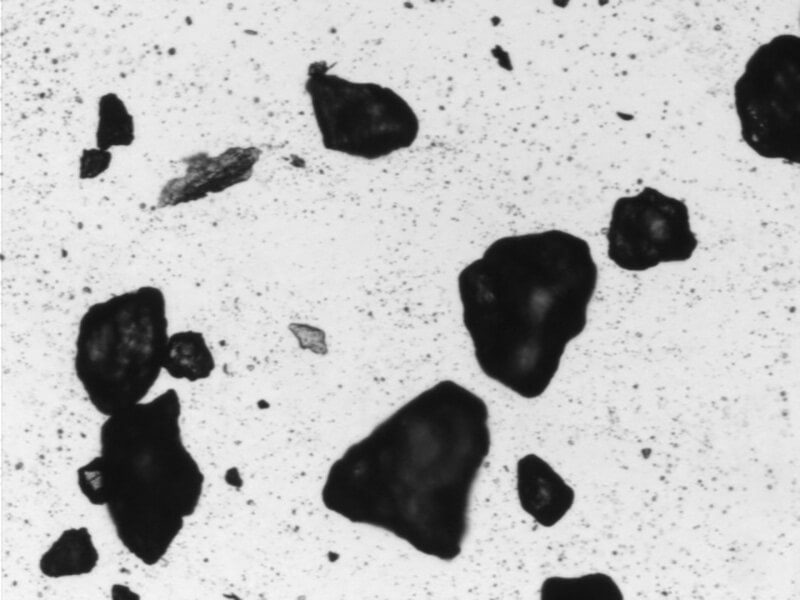

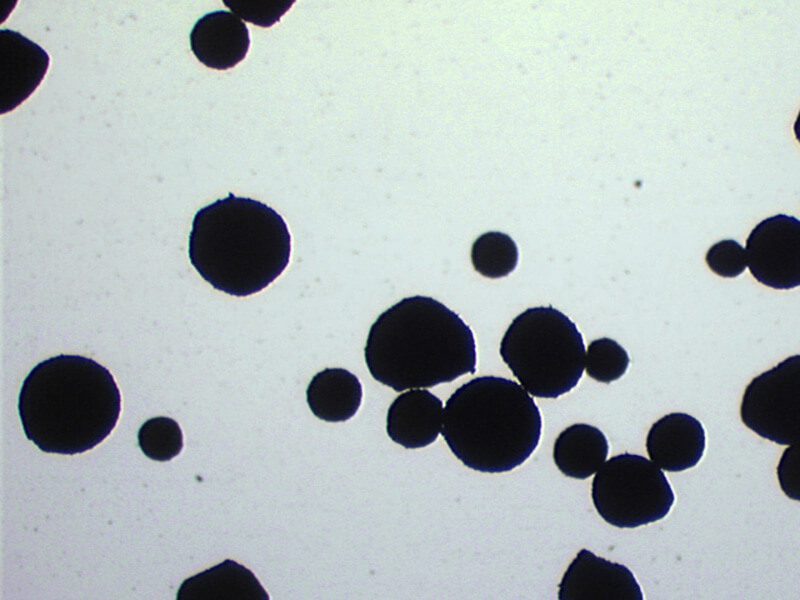

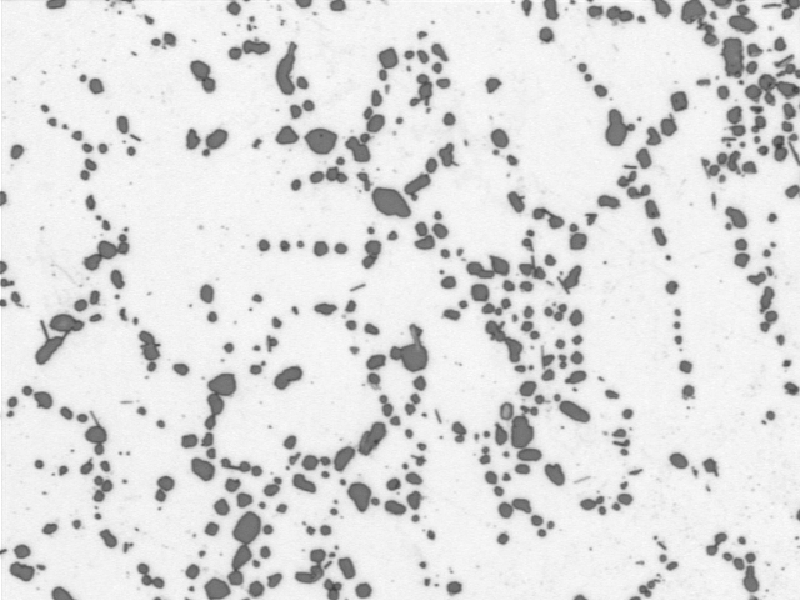

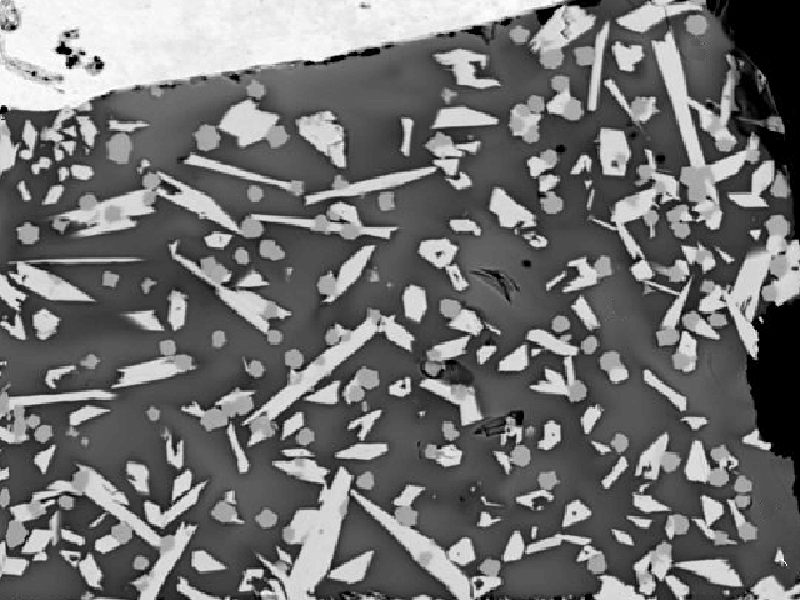

TAILLE DES PARTICULES

Permet aux utilisateurs d’évaluer de façon fiable la taille et la forme de particules

mesurant aussi peu que 0,5 micron. Grâce à la microscopie optique, cet ensemble

offre des données statistiques et individuelles sur un grand échantillon de particules.

Ce module contient huit routines différentes accompagnées d’exemples et de tutoriels.

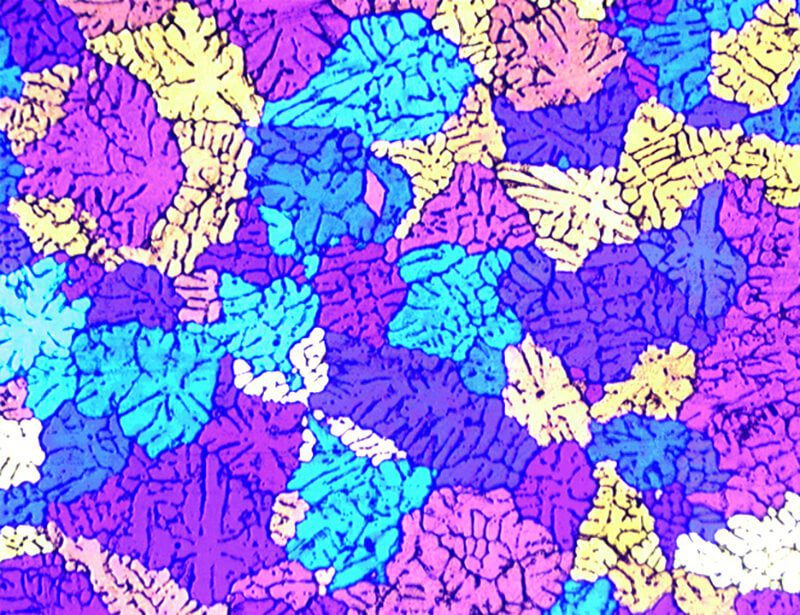

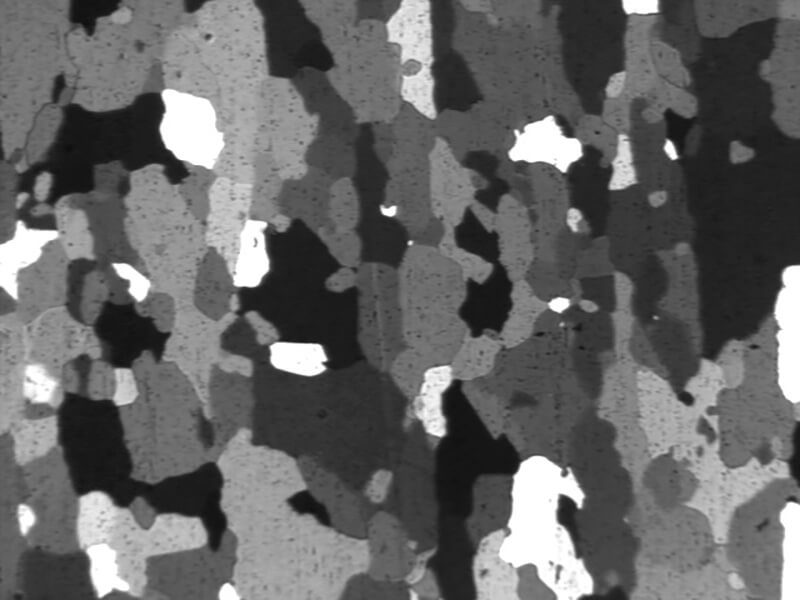

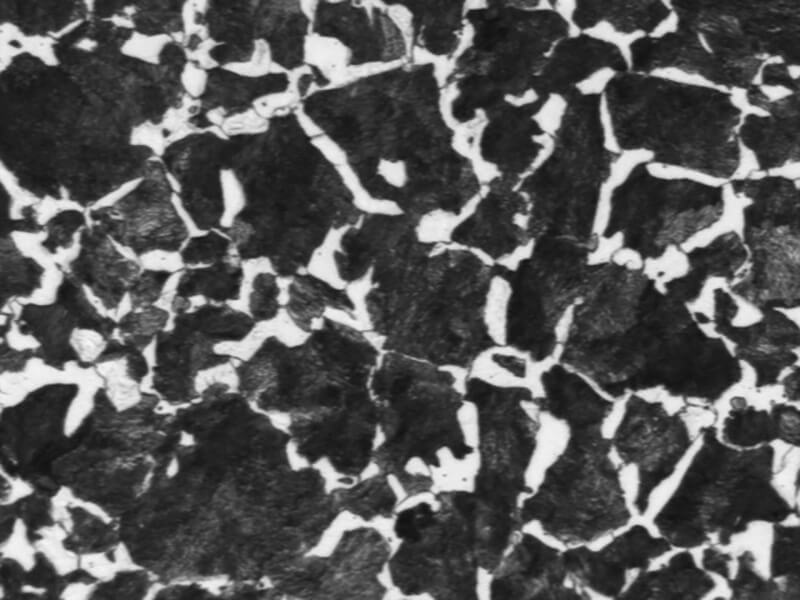

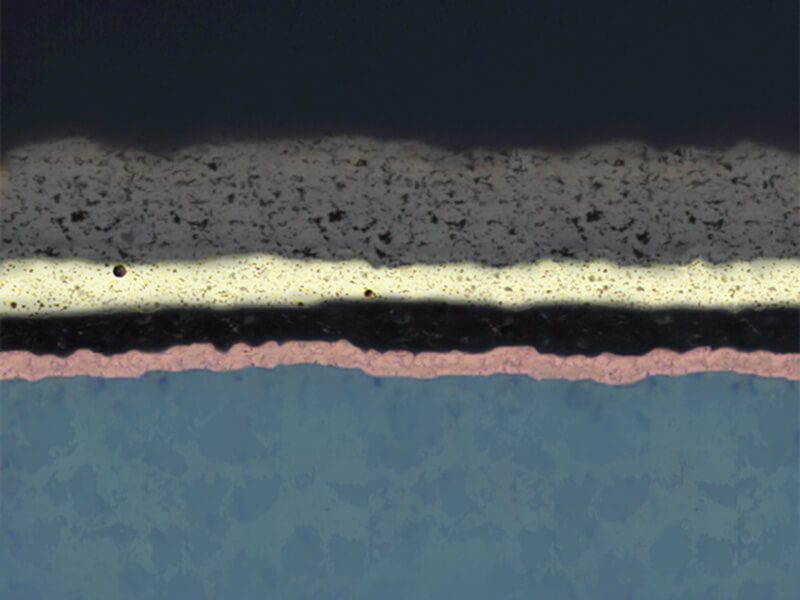

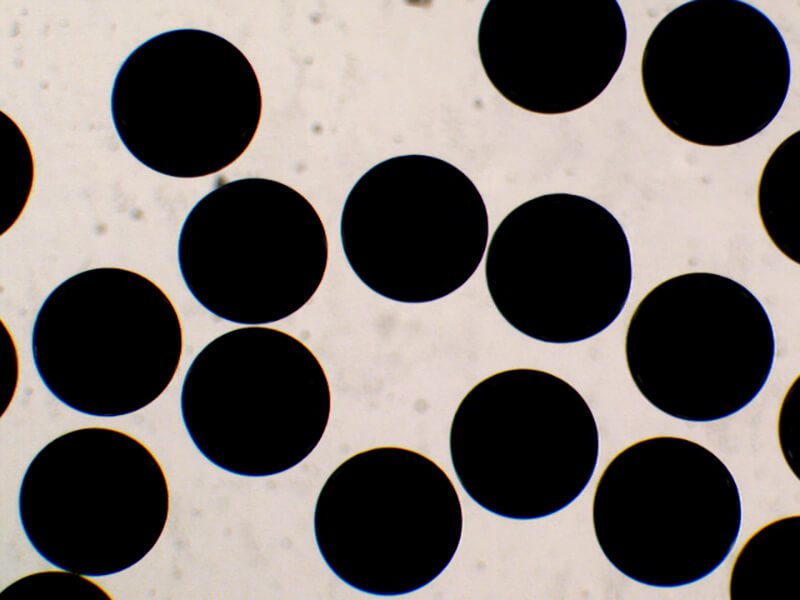

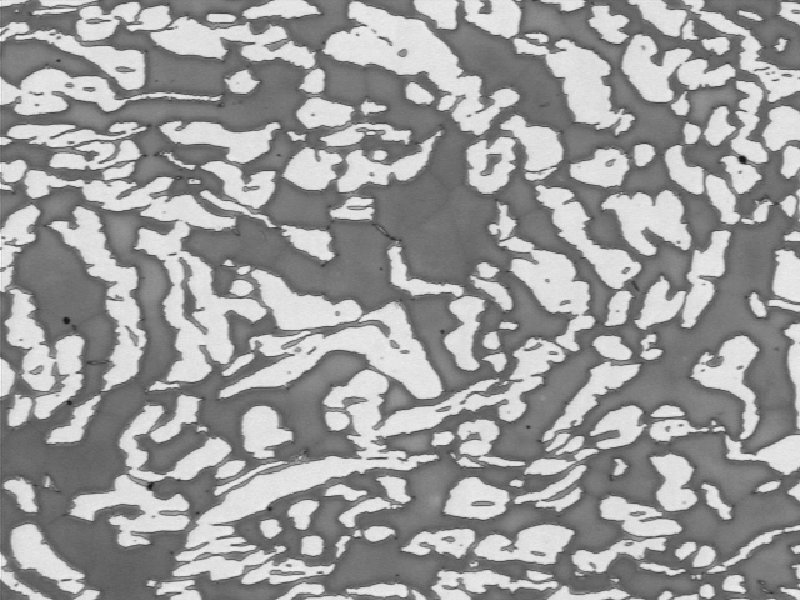

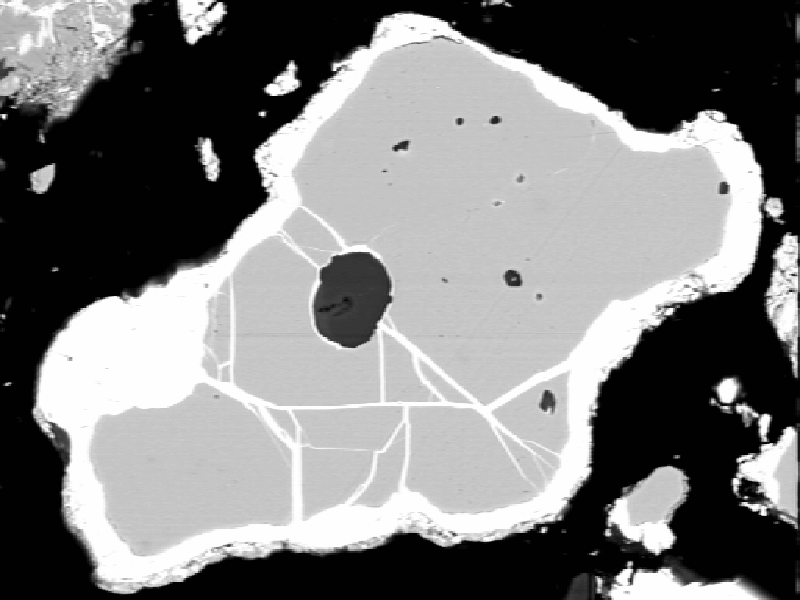

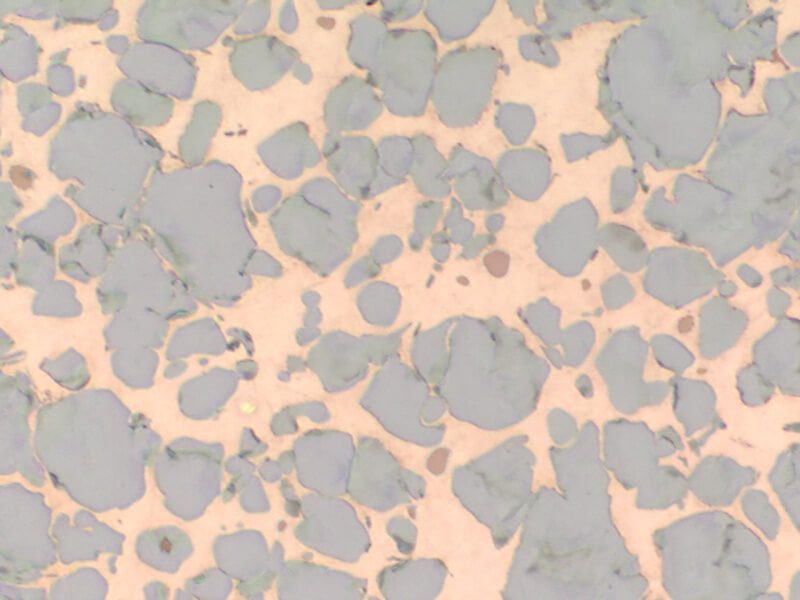

ANALYSE DE PHASE

Permet aux utilisateurs de distinguer clairement le nombre

d’éléments ou de phases au sein d’une microstructure, ce qui fournit une

estimation statistique de la fraction de volume de différentes phases.

Chaque module contient une gamme de routines différentes, allant de deux

phases en noir et blanc à cinq phases en couleur.

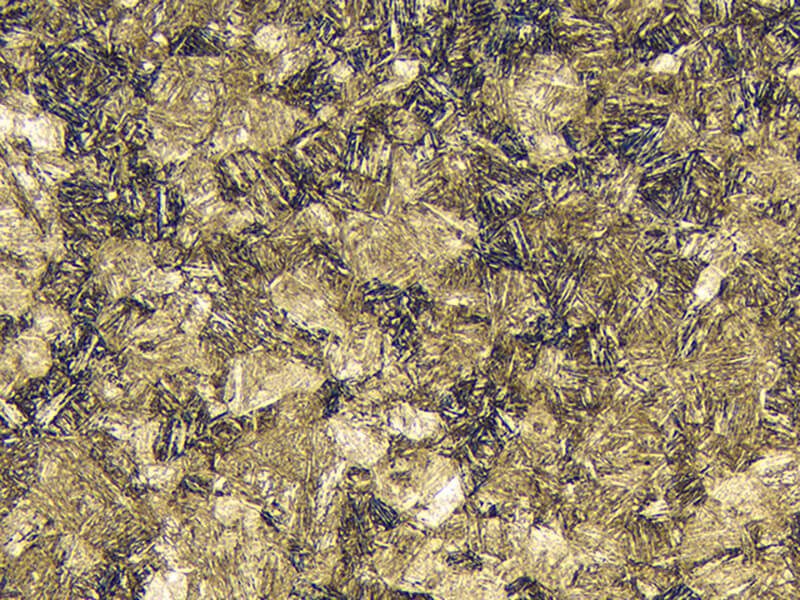

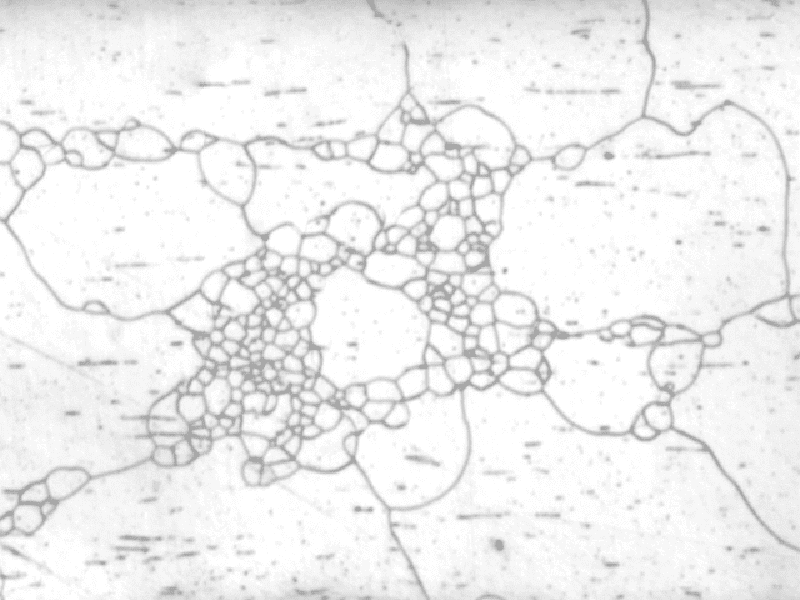

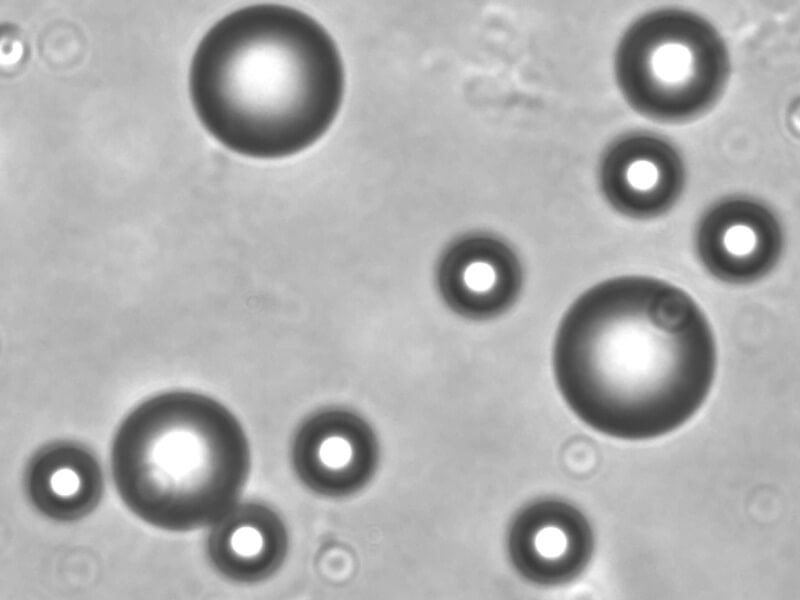

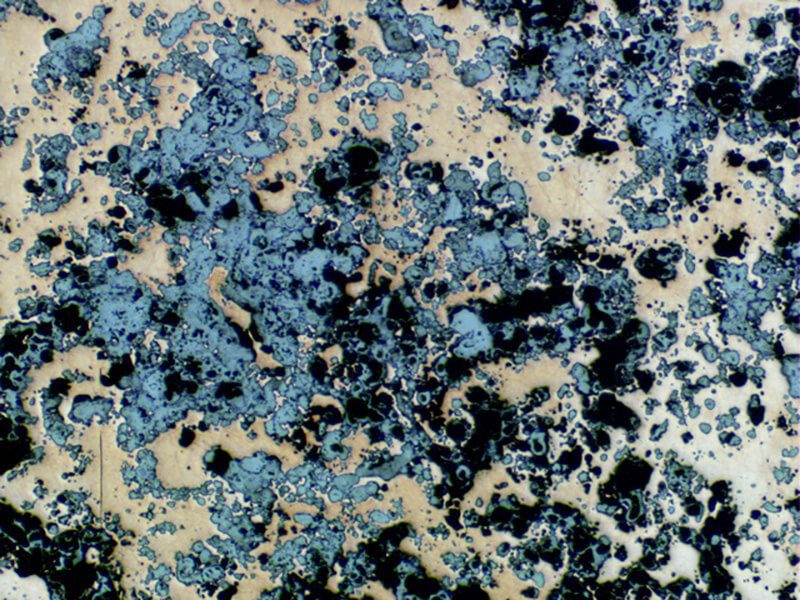

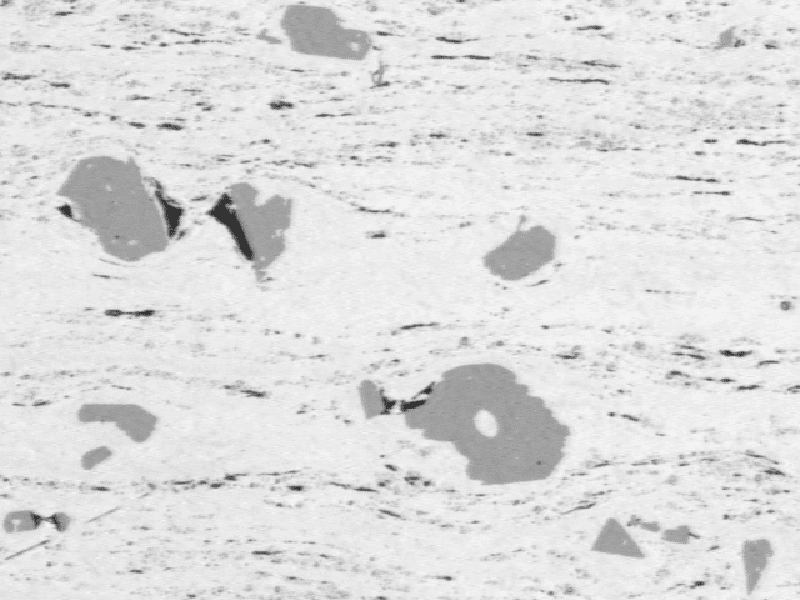

Alliages d’aluminium et de magnésium

Permet aux utilisateurs de mesurer l’espacement des cellules dendritiques,

le pourcentage moyen de l’eutectique et l’espacement linéaire moyen des dendrites

à tous les niveaux de grossissement et à toutes les résolutions de caméra